PRODUCT 제품소개

QbD/PAT

-

- 제품명

- Multichannel diode array NIR Analyzer

-

- 제조사

- SENTRONIC

-

- 상세내용

제약 QBD에서 NIR기술을 이용한 PAT(Process Analytical Technology) 장비

OVERVIEW

|

Complete PAT solution for pharmaceutical solid dose manufacturing

|

Applications

|

Continuous Manufacturing |

|

High Shear Wet Granulation |

|

Tablet press feed frame |

|

Fluid bed coating |

|

|

Roller compaction |

|

Hot melt extrusion |

More Information

A complete solution, a customizable solution

Sentronic solutions for process analysis comprise the SentroPAT FO platform, the probe and the corresponding analyzer management software. The result is a powerful, proven package that can be tailored to your specific process-monitoring needs.

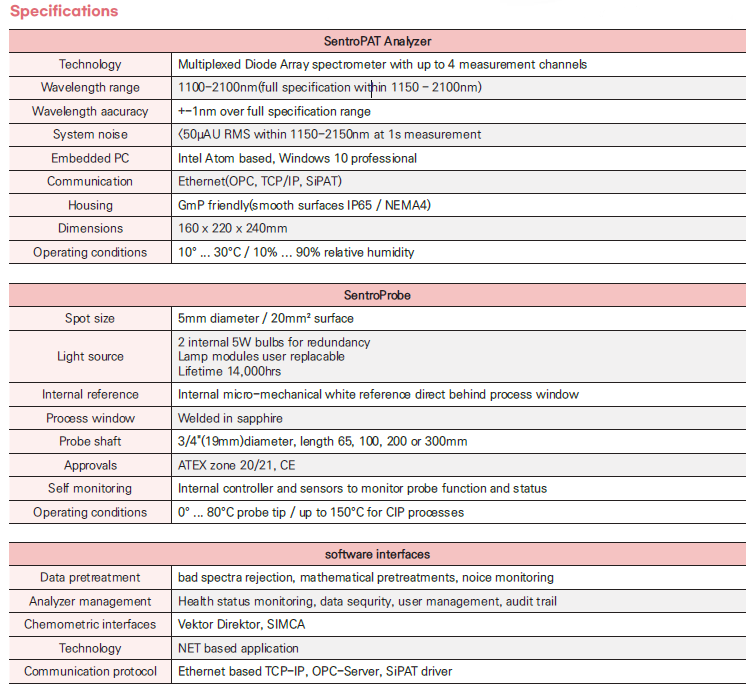

SentroPAT FO

SentroPAT FO is a compact analyzer for direct monitoring of production processes for solid-dose pharmaceuticals. It is an extremely versatile system that can be quickly and easily integrated into existing production equipment and processes. It offers extremely valuable insights into practically all process steps, such as blending, granulation, drying and compressing. It delivers precise data on input materials, process progress, product homogeneity, and the ideal process end-point. The combination of high-speed measurement and highly robust, innovative probe technology creates an exceptionally reliable tool for improved process understanding and measurement.

The NIR advantage

NIR infrared spectroscopy is the most versatile PAT technology available, with a proven track record in laboratory applications. It can be deployed to capture both physical and chemical process parameters, often rendering additional particle measurement equipment unnecessary.

Fast diode array technology

This specific NIR technology is ideal for analyzing fast-moving samples, without compromising accuracy. Measurements can be performed in milliseconds, allowing the prompt elimination of spectra with poor sample presentation.

Low maintenance

A key focus of design and development from the very outset was minimum maintenance effort and cost of ownership. The system continuously and automatically monitors all key instrument parameters, operating reliably for extended periods without user intervention. The only regular maintenance required is light source replacement, generally at intervals of one to two years. This simple task can be performed without special tools or skills.

Partnership with Sentronic

Sentronic has implemented end-to-end, fully compliant documentation across the entire product life cycle for many customers, and for many projects. We are an experienced, flexible partner. We understand that each customer has specific needs and imperatives, and we develop made-to-measure answers to the challenges of each PAT project. We are happy to play a supporting role within your existing organizational structures, providing vital input. You can be sure of effective communications, and quick, easy access to expert advice.