PRODUCT 제품소개

QbD/PAT

-

- 제품명

- Diode array NIR Analyzer

-

- 제조사

- SENTRONIC

-

- 상세내용

제약 QBD에서 NIR기술을 이용한 PAT(Process Analytical Technology) 장비

OVERVIEW

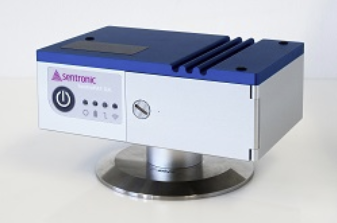

- Lightweight, compact, easy to mount

- GmP friendly with smooth surfaces

- Accurate and reliable Diode Array NIR technology

- Internal wavelength and intensity reference

- Lowest cost of ownership

- WiFi connected and battery powered

- Embedded PC for instrument control and data buffering

- Full GmP support for instrument and

- Optional Interfaces to OPC, SiPAT, SynTQ or PharmaMV

Applications

|

Bin Blending |

More Information

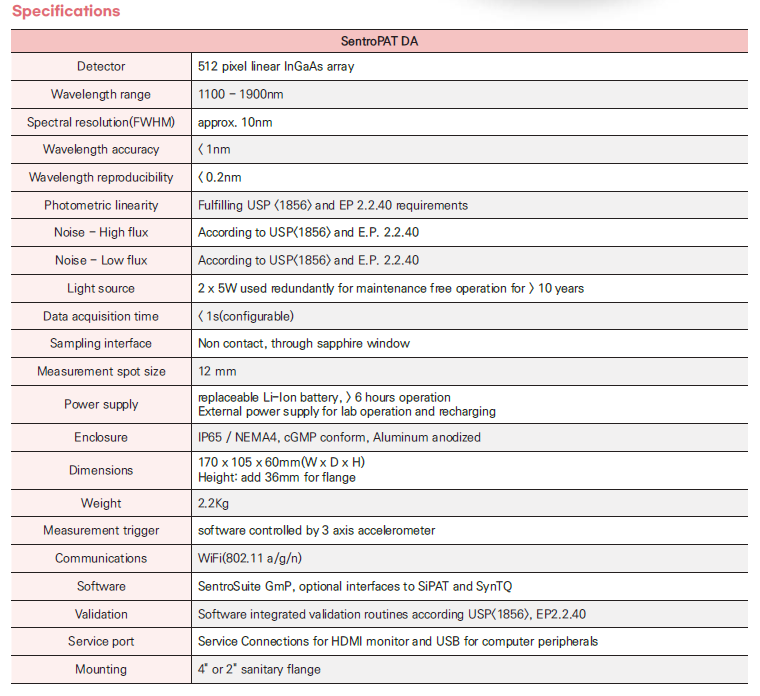

SentroPAT DA

is a dedicated NIR analyzer for non-invasive online monitoring of pharmaceutical powder blending. The system provides valuable process insight from product development to operations and can also be used to control blend time. The system fits to any size of bin blenders and containers.

High Performance Diode array spectrometer

The heart of the instrument is a rugged and proven InGaAs diode arrey spectrometer. High spectral resolution and wavelength accuary combined with low noise enable the use in demanding applications. Superior system to system comparability simplifies method transfer between different instruments. Highest long term and temperature stabiliy is supported by internal intensity and wavlength references.

Understand and control the blending process

Besides determination of blending end point by statistical methods, quantitative analysis of API and other formulation ingredients applying chemometric calibrations is possible, too. Based on the gained process data it is possible to optimize blending time, avoid faulty batches and prevent blends from being segregated due to over-blending. There is no longer need for conventional thief sampling and laboratory analysis which retard manufacturing processes and therewith raise production costs. Fully implemented and applied the online monitoring of blend uniformity is a key element for real-time release.

Flexibility and easiest handling

A key focus of design and development from the very outset was ease of use and minimum maintenance effort:

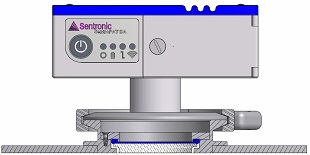

Mounting can be done by means of a simple 2" or 4” hygienic flange

- Mains adapter, internal and external charger and a hot swappable battery are providing a handling and possibilities as known from mobile PC or any other battery operated device

- The 3D orientation sensor allows software adjustable and reliable measurement synchronization to the blender rotation.

- The smooth cGMP-friendly unit can be easily cleaned, as it is required for use in GMP production facilities.

Highest data integrity

Highest data safety is guaranteed by the use of the internal embedded PC, since all generated data are buffered locally on the analyzer, before transmission through the wireless network. tandard PC periphery can be directly attached for service or IT administration. WiFi connectivity and optional OPC server are provided for the process environment.

Comprehensive support

Sentronic enjoys a unique skill set, with many years experience in development and production of spectrometer systems and probes, combined with in-depth knowledge of pharmaceutical production processes. With our engineering capabilities we are able to provide comprehensive support in any aspect of system integration into designated process environment.

Attachment to the process is made by a separate process flange with an integrated sapphire window. This flange is welded into the bin wall or into the bin lid.The inside surface is smooth and flush and will not generate any disturbancy to the blending process. We provide all necessary integration support to make that necessary modification to the equipment.

Attachment to the process is made by a separate process flange with an integrated sapphire window. This flange is welded into the bin wall or into the bin lid.The inside surface is smooth and flush and will not generate any disturbancy to the blending process. We provide all necessary integration support to make that necessary modification to the equipment.